Aircraft gear failure

One of the aviation majors entrusted us with a job to identify the root cause of aircraft gear failures (figs. a & b). We assessed the design, specifications, material, manufacturing processes, quality assessment, maintenance, application, service condition, abuse, accident, human factor & other aspects and identified the root cause to a manufacturing process resulting in the formation of hard & brittle transformation bands (figs. c, d & e) on the gear teeth resulting in failure and suggested the remedial measures.

A

Aircraft Gear Component

C

Hard and brittle transformation shear band

D

Hard and brittle transformation shear band

E

Hard and brittle transformation shear band

Benchmarking

A software MNC customer engaged us to benchmark & document automobile clutch plate assemblies (figs. a- f). The project involved inspection, imaging, determination of component & assembly characteristics (deflection, dimensions, displacement, force, surface finish , torque etc.), materials testing, material grade, manufacturing process & sequence identification, development & documentation of manufacturing drawings etc. We provided the information to the customer for manufacturing.

A

Automotive clutch plate components

B

Automotive clutch plate components

C

Automotive clutch plate components

D

Automotive clutch plate components

E

Automotive clutch plate components

F

Automotive clutch plate components

Consumer disputes

Consumer courts & judiciary have retained us to assess the technical aspects of claims, disputes & litigations. One such case involved a consumer complaint regarding a missing expensive diamond in a gold ring (fig. a). We assessed the jewellery for its characteristics and investigated the reasons for the loss of the diamond. We identified the reasons for the loss to be poor workmanship, thus assisting the judiciary decide the dispute (fig. b).

A

Buyer seller dispute regarding the workmanship of a diamond ring

B

Buyer seller dispute regarding the workmanship of a diamond ring

Contract R & D

A globally respected automobile major entrusted us with a project to determine the secondary work embrittlement behaviour in steels. We have undertaken the study involving die design & development, blanking, machining, deep drawing (figs. a & b), conditioning, testing, assessment & characterization of steel sheets (figs. c & d) between -60°C to +20°C and determined the embrittlement behavior (figs. e & f). The study provided the technical information to the company for forming automobile bodies.

A

Blanking and deep drawing

B

Blanking and deep drawing

C

Machining, conditioning, testing and assessment

D

Machining, conditioning, testing and assessment

E

Determination of embrittlement behaviour

F

Determination of embrittlement behaviour

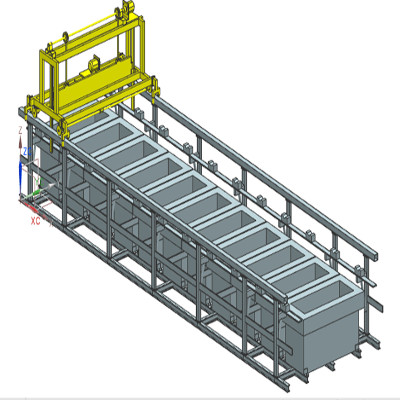

Design, Development & Engineering of SPMs & Products

We have the experience in design, development and manufacture of special purpose machines (SPMs), products & components. Examples include i) PLC based automated (appx. 10 m X 3 m X 3 m) coating & plating plants (fig. a), ii) Surface Mechanical Attrition test setup for research to study the effect of high frequency (21- 10000 Hz) impacting of vibrating steel balls and the formation of nano-crystallization behaviour in metallic materials (fig. b), iii) Mechanical connectors & lugs for joining (16 mm to 45 mm) conductors for high & medium voltage applications (fig. c).

Our design services has resulted in our customers making global patent applications.

A

Automated coating and electroplating plant

B

Surface Mechanical Attrition treatment setup

C

High voltage mechanical connector

Fire incidents, accidents and insurance claims

Many reputed insurance companies have entrusted us to assess the technical aspects of fire incidents, insurance claims, burglaries & accidents involving transmission towers, LPG lines and tobacco, turmeric, areca nut, cashew, jute & other godowns, jewellery shops & electronic component storage houses etc. (figs. a- f). We have conducted product & circumstance specific special tests & studies and determined the cause for the incident, quality of items & estimated the quantity of the goods affected. These studies have helped insurance companies to assess the veracity of the claims.

Performance assessment

A health care equipment manufacturer has retained us to assess the performance & reliability of lullaby warmers, patient tables, ultrasound scanners (figs. a- c) etc. We have conducted the tests simulating the actual service conditions by barrier impact, threshold resistance & other tests and assessed the reliability & safety of products. We have identified the components with inferior performance and short service life.

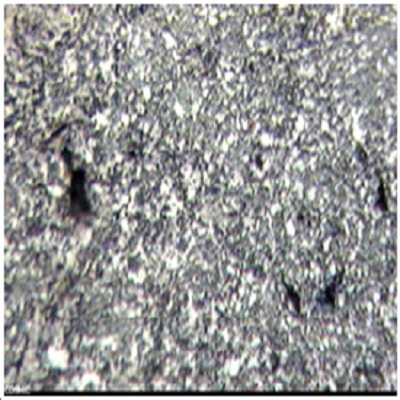

Product development

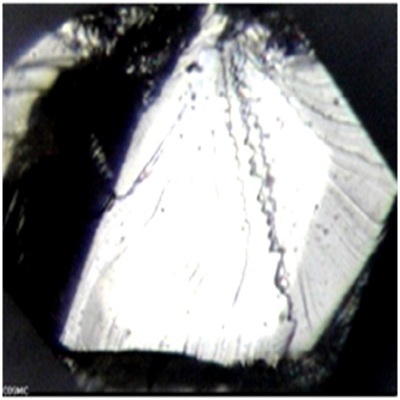

We have executed a project for a company engaged in granite cutting, polishing & exporting involving the development of granite cutting segments (fig. a). The project involved materials selection, analysis, design, mixing, compacting, sintering, microstructural evaluation (figs. b), testing, validation, performance assessment of diamonds (figs. c- e) & documentation of development & manufacturing processes. The study resulted in the manufacture of the segments.

A

Granite cutting segment

B

Microstructural evaluation

C

Performance assessment of diamonds

D

Performance assessment of diamonds

E

Performance assessment of diamonds

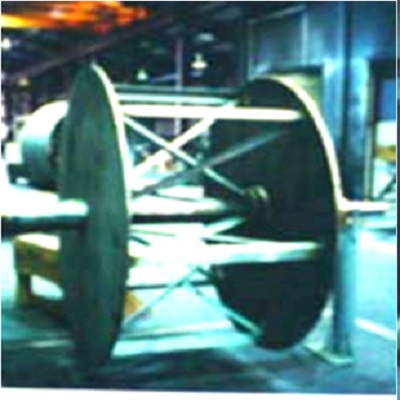

Prototype development and pilot production

We have the experience in designing, developing & manufacturing i) production machinery (figs. a & b) for a foil manufacturing company to address the manufacturing problems, down time, production loss & improve product quality, ii) a heat exchanger (fig. c) to replace an aged imported heat exchanger for a major food processing company and iii) high altitude telescope (fig. d) to observe a comet at an altitude of 40 km from the earth's surface . The project involved design, materials selection, ring rolling, dissimilar metal welding, engineering, fabrication, assembly, testing, pilot production, validation & assessment of machinery and the assessment of products manufactured using the newly developed machinery based on new ideas, materials, design & manufacturing processes. The first project resulted in saving millions of dollars annually and manufacture of superior products. The second project led to indigenously manufacture at approx. 30% cost and thus saving foreign exchange. The third project led to the capture of highly coveted images of the comet ISON as it approached the sun, in a cost effective manner.

A

Electrofoil manufacturing support

B

Electrofoil manufacturing support

C

Heat exchanger manufacturing

D

High altitude telescope fabrication

Reliability assessment

Manufacturers have entrusted us to assess the performance & reliability of automotive seats & springs, fluid dispensing valves, solar panels (figs. a & b), swinging doors, windmill blades (fig. c) etc. We have assessed behavior & performance of products under different service conditions (at different static & cyclic loads at ambient & low temperatures). The studies resulted in predicting the service life of the products in real-world conditions.

Remnant life assessment

We have assessed the remnant life of boilers, condenser heads, hydro turbines, locomotive gears (figs. a, b, c & d respectively), silos and other large structures by various NDE & lab tests. The study helped our customers decide the nature & extent of service needed to ensure the safety & reusability. It provided inputs to the users to take critical decisions with regard to maintenance, repair (or replacement), safety, service life etc. In certain cases, our studies also helped the customer to make an informed decision on making fresh investment for replacing the machinery.

Welding process development

We have developed arc, TIG and SAW welding processes for defence, locomotive, shipbuilding and structural applications.

A

TIG and SAW welding process development

B

Arc welding for locomotive application